1. Ƴeewndo mbaydi

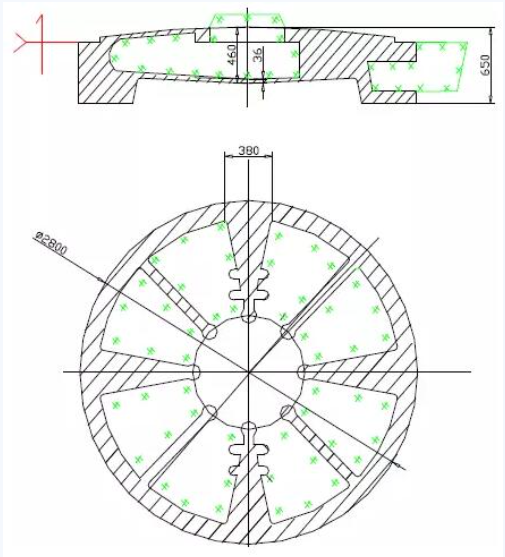

(1) Ɗuumvalve buubaajiina jogii mbaydi cirƴaandi no kaake nii, ɓuuɓol nder ngol ina jokkondiri e ina wallita e 8 ƴiye semmbinooje, ɓuuɓol dow ngol Φ620 ina jokkondiri e ɓuuɓol nder ngol, heddii ko...valveina udditii, ƴiiƴam njaareendi ina saɗi feewnude, ina weeɓi kadi ɓuuɓde. Ekkol e laɓɓingol ɓuuɓri ndernderi ndii fof ina ngaddana caɗeele mawɗe, hono no hollirtee e Natal 1 ngal nii.

Tekkeendi mahol ngol ina seerti no feewi, tekkeendi mahol ɓurndi mawnude ina yettoo 380mm, tekkeendi mahol ɓurndi famɗude ko 36mm tan. So tawii ɓuuɓri ndii ina tiiɗi, ceerungal nguleeki ina mawni, tee ɓuuɓri ndi fotaani ina waawi saabaade ɓuuɓri ɓuuɓri e ŋakkeende porositee ɓuuɓri, ko ɗum addanta ndiyam ɓuuɓde e jarribo hidrolik.

2. Faandaare golle :

(1) Ɗaɗi ceertuɗi ɗii kolliraama e natal 1. Waɗde joofnirde ndee ina waɗi ɓulli e dow kees toowɗo oo, mbaɗa heen ɓuuɓri ceene ndii fof e nder ɓuuɓri hakkundeeri ndii, njuuteendi hoore ceene ndee no haanirta nii ngam weeɓtinde jokkondire ceene ɗee e yahdu ceene ɗee so kees oo wirnaama. Tabitɗo, njuuteendi hoore core cantilever e ɓulli ɗiɗi wumɓe e bannge ina ɓuri njuuteendi ɓulli ɗii, haa noon cakkital teddeendi core sanngara oo fof ina bias e bannge hoore core ndee ngam tabitinde core sanngara ɗee ina tabiti, ina dartoo.

Siistem werlaade semi-udditiiɗo ina huutoree, ∑F nder: ∑F dow: ∑F juutɗo=1:1.5:1.3, sprue huutortoo ko tuuba seraamik mo njaajeendi nder mum ko Φ120, e pecce ɗiɗi prevent to 100yfractort aretomd the bricks mo njamndi ummoraade e toŋngoode Ngam ɓuuɓnude njaareendi, filtirde seraamik foam 150×150×40 ina joɗɗinaa e les dogdu nduu, e 12 tuubaaji seraamik jogiiɗi njaajeendi nder Φ30 ina kuutoree ngam dogdu nder nduu jokkondirde e les filtirde ndee form to bolleut rewrude e ndiyam colleut skema rufde, hono no hollir-ɗen e Natal 2 Essence

(3) Waɗde 14 ∮20 ɓulli henndu e nder mooftirgel toowngel, waɗde Φ200 ɓulli ɓuuɓɗi core ceene e nder hakkunde hoore core, waɗde njamndi coofndi e nder pecce tedduɗe e mawɗe ngam tabitinde solidification ballondiral e ɓuuɓri, e huutoraade graphitization yaajde feere yidsel ngam huutoraade laawol yaajde ngol. Mawneeki kees ceene oo ko 3600×3600×1000/600mm, ina weltinaa e 25mm njuuteendi njamndi ngam tabitinde semmbe e tiiɗnaare no feewi, hono no hollir-ɗen e Natal 3 nii.

3. Hakkilanki golle

(1) Modeling: Before modeling, use a Φ50×50mm standard sample to test the compressive strength of the resin sand ≥ 3.5MPa, and tighten the cold iron and the runner to ensure that the sand mold has sufficient strength to offset the graphite produced when the molten iron solidifies Chemical expansion, and prevent the molten iron gila e mettinde feccere dogdu nduu ko juuti ngam saabaade lootgol njaareendi.

Waɗde core : Core sanngara ina feccii e pecce 8 potɗe e 8 ƴiye semmbinooje, ɗe njokkondirta ko e ɓuuɓri hakkundeeri. Alaa geɗe goɗɗe ballitooje e ɓuuɓɗe so wonaa hoore core hakkundeere. So tawii core ceene ɗee mbaawaa fiɓde e Exhaust, core ceene ɗee diƴƴe e ɓulli henndu maa peeñ caggal nde ɓuuɓnaa. Sabu keewal ɓakdi sanngara ina mawni, ina feccii e pecce jeetati. Ina haani nde jogoo semmbe e tiiɗnaare no feewi ngam haɗde ƴiiƴam ɗam bonnaade caggal nde ɓuuɓri ndii yalti, kadi ndi bonnataa caggal nde ndi werlaa. Deformation ina waɗa, ngam tabitinde njuuteendi murliɗi gooti e ɓuuɓri. Ngam ɗuum, min mbaɗi teeŋti noon e ƴiyal core keeriiɗo, min ndarni ɗum e ƴiyal core ngal e ɓoggol weeyo ngam ittude gaas gonɗo e hoore core ndee ngam tabitinde compactness mooftirgel sanngara nde min mbaɗata core ndee. No hollir-ɗen e Natal 4 ngal nii.

(4) Kaɓirgal udditirgal : So en teskiima wonde ina saɗi laɓɓinde ceene e nder ɓuuɓri nder ɓuuɓri ɓuuɓri, ɓuuɓri ceene ndii fof ina pentiree laabi ɗiɗi pentiir, laabi gadani ɗii ina njuutee e pentiir zirkonium baɗɗo alkol (Baume degree 45-55), laabi gadani ɗii ina pentiree e burne. Caggal nde njuumri ndii yoori, pentir laral ɗiɗaɓal ngal e pentirgal magnesium (Baume degree 35-45) ngam haɗde ɓuuɓri ndii ɓuuɓde e ceene e sintering, ndi waawataa laɓɓineede. Feccere hoore core ndee ina fawee e dow tuuba njamndi Φ200 mo mbaydi mawndi ƴiyal core ngal e ɓoggi M25 tati, fiɓnde e coktirgal e kees ceene mooftirgel toowngel e ɓoggi ɓoggi e ƴeewteede so tawii teddeendi mahol kala feccere ina nanndi.

4. Laawol fuɗɗude e rufde

(1) Huutoro Benxi lowre-P, S, Ti toownde Q14/16# njamndi mboɗeeri, ɓeydu heen 40%~60% ; mborosaaji ko wayi no P, S, Ti, Cr, Pb ekn ina njuɓɓinee no feewi e nder njamndi mboɗeeri, tee alaa ko waawi heen wonde so wonaa mboros e nebam , ɓeydagol ngol ko 25%~40% ; charge gartiraaɗo oo ina foti laɓɓineede e ɓuuɓri hade mum huutoreede ngam tabitinde laaɓal charge oo.

(2) Main component control after furnace: C: 3.5-3.65%, Si: 2.2%-2.45%, Mn: 0.25%-0.35%, P≤0.05%, S: ≤0.01%, Mg (residual): 0.035% ~0.05%, under the premise of ensuring spheroidization, the lower limit of Mg (residu) ina foti ƴetteede no waawirtee.

(3) Safaara inokulaasiyoŋ sferoidisaasiyoŋ : sferoidisaasiyoŋ lowre magnesium e lowre rare-earth ina kuutoree, tawa noon ɓeydagol ngol ko 1,0%~1,2%. Laawol ɓuuɓngol gaadoraangol ngol ko safaara sferoidisaasiyoŋ, 0,15% e inokulaasiyoŋ gootol ina suwee e dow nodulizer to les paaspoor oo, sferoidisaasiyoŋ oo ina timma. Ndeen vursugol ngol ina subkontraa ngam vursugol zii 0,35 %, vursugol ngol 0,15 % ina wazee e sahaa vursugol ngol.

(5) Lowre nguleeki yaawnde rufde laawol ina jaɓee, rufde nguleeki ko 1320°C~1340°C, e waktu rufde ko 70~80s. Njamndi mboɗeeri ndii waawaa taƴde e nder wertallo, kadi koppi sprue ɗii ina keewi sahaa kala ngam haɗde gaas e naatgol naatde e mooftirgel ngel rewrude e dogdu nduu. ɓuuɓri.

5. Njeñtudi jarribo casting

(1) Fotde semmbe ɓuuɓgol bolol jarriborgol ɓuuɓngol : 485MPa, juutgol : 15%, tiiɗndam Brinell HB187.

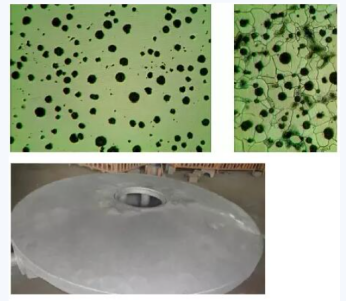

(2) Hakindo sferoidization ko 95%, mawneeki grafit ko tolno 6, perlit ko 35%. Ko mbaydi njamndi ndii hollitaama e Natal 5.

(3) Alaa ŋakkeende winnditaande tawaa e UT e MT ŋakkeende ɗiɗmere detektirgal geɗe teeŋtuɗe.

(4) Nafoore ndee ko ɓuuɓnde, ɓuuɓnde (ƴeew natal 6), tawa alaa ko bonnata ɗum so wonaa ɓuuɓri ceene, ɓuuɓri ɓuuɓri, ɓuuɓri ɓuuɓri ekn, teddeendi mahol ngol ina woodi, kadi dimensiyonji ɗii ina njahdi e sarɗiiji natal ngal.

(6) 20kg/cm2 jarribo vurngo moxxude caggal nde golloraa hollirtaa hay vursugol gootol

6. Ciimtol

E fawaade e sifaaji mbaydi ndii valve buubaaji, caɗeele deformaasiyoŋ mo dartaaki e weeɓde e nder njuuteendi njaareendi mawndi e nder laɓɓingol njaareendi hakkundeeri e caɗtundi, ina safree e teeŋtinde e peewnugol peeje golle, peewnugol e fiɓnde njuuteendi njaareendi e huutoraade coftal baɗngal zirkonium. Setting ɓulli vent ina reena mbaawka pores e nder castings. Gila e njuɓɓudi charge furnace e dogdu, ekran filtirde seraamik foam e karallaagal ingate seraamik ina kuutoree ngam tabitinde laaɓal njamndi mboɗeeri. Caggal safaaraaji keewɗi inokulaasiyoŋ, mbaydi metallographic castings e ceertuɗi Golle kuuɓtodinɗe ɗee njottiima e sarɗiiji njuɓɓudi soodooɓe

DigaTianjin Tanggu Koolaaɗo kuuɓal ndiyam-ɓalndu. Valve buubaaji, valve damal, Y-siiloowo, wafer ɗiɗo plaque ƴeewndo valvepeewnugol.

Waktu posto: 29-Abriil-2023